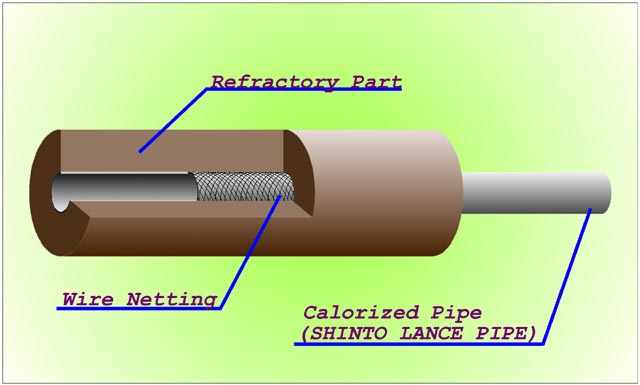

Developed as an extension of the Shinto Lance

Pipe , the heavy - coated lance uses advanced heat-insulating materials.

It offers excellent performance for use in

the manufacture of stainless and alloy steel

in electric arc furnaces , ladle furnaces,

VAD and VOD . |

|

|

|

|

|

Click above picture and you can get the enlarged

picture!! |

|

Pipe |

|

SHINTO LANCE PIPE (calorized) |

|

Refractory |

|

Offers higher resistance against spalling,

and offers enhanced durability without exfoliation

in molten steel. |

|

<Chemical composition (Refractory)>

| Click each images, you can see enlarged photos. |

|

|

| Lance Pipe |

On operation |

| for E.A.F. |

for Pre-treatment process/iron

for L.F./V.O.D. |

| Al2O3 |

66 - 76 |

Al2O3 |

65 - 75 |

| SiO2 |

21 - 26 |

SiO2 |

22 - 28 |

| TiO2 |

1 - 3 |

|

|

| Fe2O3 |

< 0.5 |

|

|

| Na2O + K2O |

2 - 4 |

|

|

| CaO |

< 0.5 |

|

|

| MgO |

< 0.5 |

|

|

| T.C |

- |

|

|

| Specific Gravity |

2.1 |

Specific Gravity |

2.6 |

|

|

1. |

Oxygen /argon injection in EAF , LF , VOD

and VAD |

|

2. |

Pre-treatment of hot metal (de-sulfur , de-phosphorous

) |

Shinto Lance Pipe |

|